|

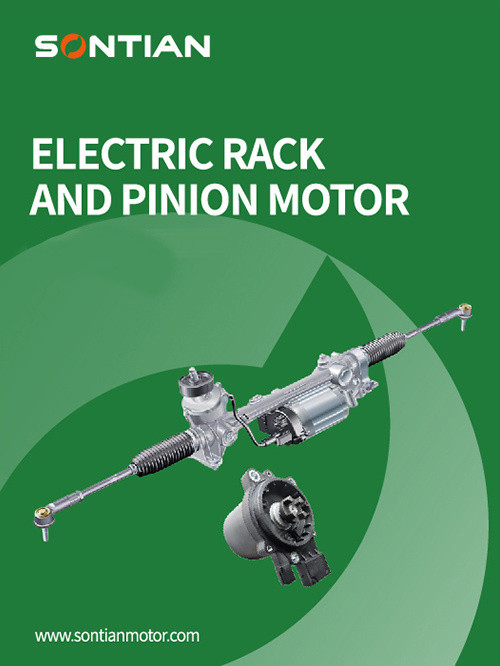

ELECTRIC RACK AND PINION MOTOR

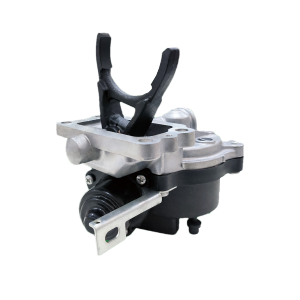

EPS motor, also known as electronic power steering motor, applies force to the rack through a small gear, which means that the steering column and motor are parallel coupled to the rack in the same mechanism (such as ball screw or circulating ball). Composed of EPS controller, torque sensor, motor assembly, and deceleration device, it is a new generation electric power steering device for automobiles.

The electronic power steering system has an electric power assist machine that directly provides steering assistance, eliminating the necessary power steering oil pump, hoses, hydraulic oil, conveyor belts, and pulleys installed on the engine for hydraulic power steering systems. It is characterized by energy savings, flexible assembly, and the ability to provide specialized assistance in various situations. The microcomputer control unit determines the size and direction of steering assistance based on signals from the steering sensing device and vehicle speed sensor, and drives the motor to assist in steering operations.

Product advantages

1. Reduce fuel consumption: The system is only powered by the motor during turning and does not consume energy when not turning, thereby reducing the vehicle's fuel consumption.

2. Better response speed and tracking performance: Using a permanent magnet brushless DC motor, the motor efficiency is higher.

3. Good centering performance: The system can be adjusted through software to make the vehicle turn easily at low speeds and handle well at high speeds. At the same time, the centering performance of the steering wheel is good, improving the stability of the car.

4. Easy to maintain: The system has a simple structure, light weight, and is conducive to later maintenance.

5. Convenient implementation of autonomous driving.

|